Common Questions about NEMA Standards and ISO Containers

Paige Welsh | Nov 2, 2017

Paige Welsh | Nov 2, 2017

NEMA electrical enclosures hide in plain sight all around us. If you go for a quick look around your office or home, you’ll probably find one protecting your circuit breakers. Equipment enclosures aren’t glamorous, but they play a key role in protecting equipment and, most importantly, people. Their standards can also be applied to larger prefab shelters built within ISO containers.

The electrical enclosures inside a typical home are just the beginning when it comes to protecting electrical equipment. Work sites often require specialized protection. For example, if a construction team needs to protect outdoor electrical equipment, they need an enclosure that keeps out cement dust and inclement weather. Meanwhile, a brewery which regularly hoses down its work space will need an enclosure that’s water tight.

Parsing through the specs for each type can be difficult reading for people without an engineering background. To assist those project managers and product procurement specialists who are scratching their heads over the difference between a Type 5 and a Type 12 enclosure, we’ve answered a few common questions with the help of our expert electricians.

Can pre-fab container shelters (large enough for a technician to walk inside) be NEMA compliant?

Can pre-fab container shelters (large enough for a technician to walk inside) be NEMA compliant?

NEMA standards are applied to enclosures, structures that are too small to for a person. Enclosures range from the size of shoe boxes to cabinets. Protective structures around the size of the shipping containers (see adjacent image) are generally referred to as shelters because technicians can walk inside them.

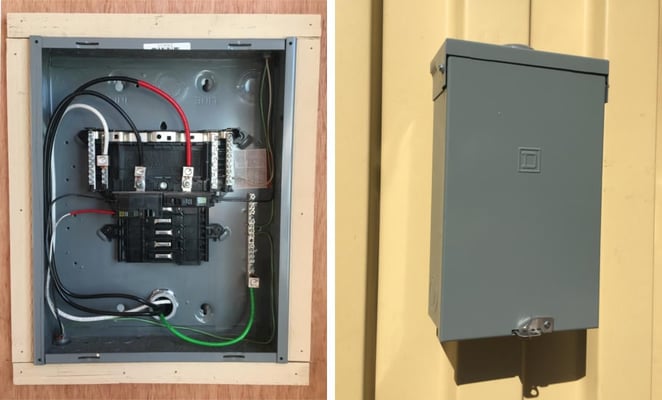

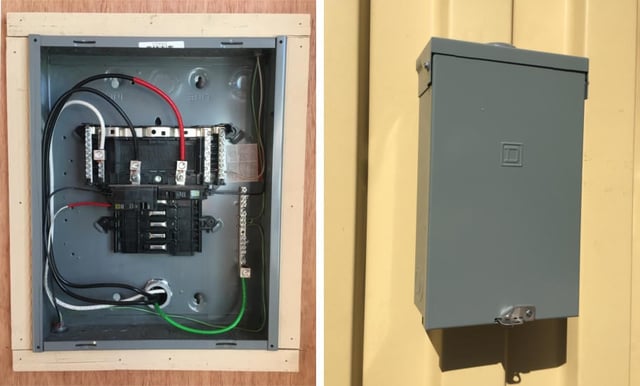

While an equipment shelter probably won't receive official NEMA recognition, many modular shelter manufacturers will use NEMA standards as a useful shorthand for features and functionality. Thus, manufacturers will describe their shelters as Type 3R, but not go so far as to say they are NEMA Type 3R. To further complicate matters, prefab shelters may contain smaller NEMA equipment enclosures, like in the photos below.

You can find a Type1 enclosure (left) in most homes and offices. We installed this weather resistant Type 3R enclosure(right) on the outside of a shipping container office.

What is NEMA?

The National Electrical Manufacturers Association (NEMA) describes itself as, “the association of electrical equipment and medical imaging manufacturers.” Their expertise ranges from the manufacture of MRI machines to lighting systems.

What is a hazardous location?

Hazardous locations tend to pose high risks of explosions or fires; think mines and oil drilling sites, or factories with circulating, flammable dust. Enclosure Types 7, 8, 9, 10, and 11 are built for hazardous locations.

What does each enclosure type protect against?

We have summarized the different enclosure types in the following charts. Because enclosures built for hazardous locations have specialized standards beyond the scope of our usual work, we’ve focused on the more common enclosures built for non-hazardous locations.

Where can I learn more about the protections listed in the chart?

For more details on the charts above, check out our guide, “NEMA Standards in Plain English.”

Can these enclosures have openings for ventilation?

Enclosure types 1, 2, 3R, 3RX may have openings for drainage and ventilation if the enclosure can still offer the protections described in the standard. For example, an enclosure with thoughtfully placed ventilation slats could still protect equipment from falling dirt and occasional splashing. Since 2, 3R, 3RX may be exposed to splashing water, NEMA requires drainage openings to accompany ventilation openings.

Can one enclosure meet multiple standards?

Yes. For example, a Type 4 enclosure is splash resistant and dust-tight, while a Type 2 enclosure is only splash resistant. Since the Type 4 enclosure meets Type 2 requirements (splash-resistance) and more, it can be used as a Type 2 enclosure. However, because enclosures with additional protective features generally cost more, most businesses use an enclosure that meets the needs of the situation and nothing more.

Looking for a faster solution for industrial equipment protection? Give us a call at 877-704-0177 or email us.

SUBSCRIBE

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

Shipping Containers are Joining Building Code. Now What?

Paige Welsh | Feb 27, 2019 | 2 min read

READ MORE

First Responder Training Facilities in Modified Shipping Containers

Paige Welsh | Oct 11, 2017 | 4 min read

READ MORE

New Boxpert Investigates the Art of Modifying Shipping Containers

Paige Welsh | Aug 9, 2017 | 4 min read

READ MORE