All-Metal Locker Room for a Compressor Station

Paige Welsh | Mar 27, 2019

Paige Welsh | Mar 27, 2019

Industrial work in remote locations will probably never be glamorous, but small measures can make a big difference in an employee’s decision to stay or look for other opportunities. A full bathroom with running water and personal storage space makes difficult weather manageable and it sends a message. When a company invests in assets that support comfort, it’s a reminder that leadership appreciates their employees’ work. Here’s an example of a customer who used an all-metal locker room built inside a shipping container to do just that.

The People Behind Natural Gas Infrastructure

Williams builds and maintains energy infrastructure. Part of their work includes operating and maintaining pipelines for natural gas. Gas crosses hundreds, often thousands of miles from the extraction sites to their final destinations. To move it along pipelines, Williams funnels natural gas into enormous engines called compressors. Once the gas is pressurized, it moves around 25 miles per hour down the pipelines to people’s homes.

Keeping these compressors safe requires regular maintenance and check-ups from technicians. However, because compressor stations are usually placed in remote locations, energy companies like Williams rely on portable support structures like trailers and portable toilets. Needless to say, coming to work every day and using a porta-potty gets old for employees - fast.

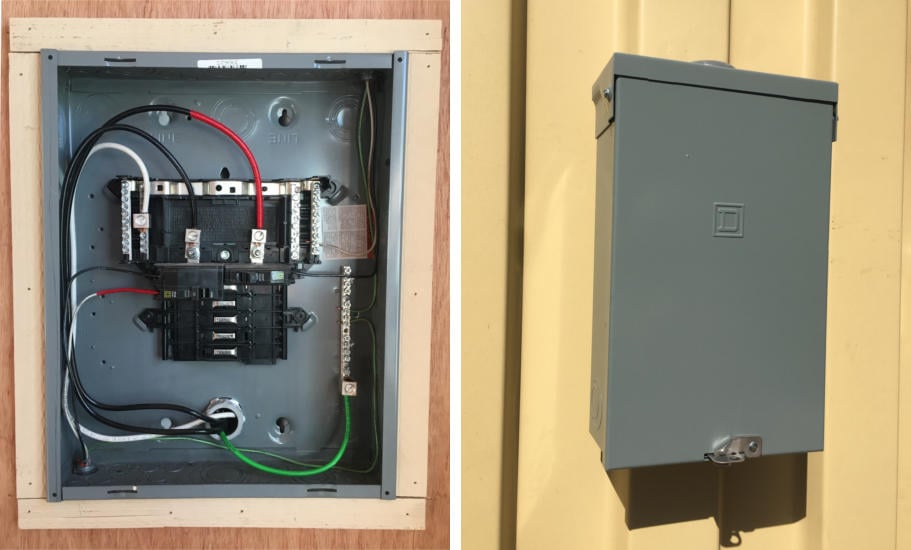

Williams wanted to create a locker room with flush toilets and a shower to improve its employees’ working conditions and hiring retention, but there were also some other requirements that must be satisfied:

- The structure could not include lumber.

- While Williams doesn’t have immediate plans to relocate the locker room, the business preferred to invest in a structure that could be picked up and redeployed.

Containerized Locker Rooms Boost Morale and Retention

A shipping container locker room built out with metal studs and walls fit the bill. Alongside Williams’ preferred lockers with lockboxes, the locker room includes a high-powered air conditioning system and a shower.

With a containerized locker room:

- Employees get a place to shower, change, and store cold-weather gear.

- Williams boosted morale and made their business a better place to work.

- Williams created a long-term solution that can be relocated in the future.

While Williams’ design was unique, we’ve seen other industrial customers succeed with similar employee retention strategies. To learn more check out:

- A dual-gender restroom building for remote oilfields.

- Our standard 40-foot locker room floor plan.

About Williams

Williams is an energy infrastructure company focused on connecting North America’s significant hydrocarbon resource plays to growing markets for natural gas and natural gas liquids (NGLs). Williams’ interstate gas pipeline and gathering & processing operations span the United States, including strategic assets in the deepwater Gulf of Mexico, the Rockies, the Pacific Northwest and the Eastern Seaboard.

SUBSCRIBE

- Shipping Container Modifications

- How-Tos

- Workspace

- Commercial Construction

- Multi-Container Buildings

- Storage Solutions

- Industrial Enclosures

- Bathrooms & Locker Rooms

- Oil & Gas

- Climate Control

- Green Building

- Industry Insight

- Living Space

- Military & Training Facilities

- Water Treatment Solutions

- Energy

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

Shipping Container Permitting Terminology

Paige Welsh | Jan 10, 2019 | 4 min read

READ MORE

Common Questions about NEMA Standards and ISO Containers

Paige Welsh | Nov 2, 2017 | 3 min read

READ MORE

Green Office Ideas and Portable Solar Power with Shipping Containers

Stephen Shang | Nov 10, 2014 | 3 min read

READ MORE