Why Shipping Containers Make Ideal Motor Control Center Enclosures

Marissa Morin | Oct 13, 2021

Marissa Morin | Oct 13, 2021

Back in the 1950s, the automobile industry was the first to commonly use motor control centers (MCCs) to accommodate the large number of electric motors used in manufacturing. Today, many industrial and commercial companies rely on MCCs to keep electric motors and other devices in a central location. Although many MCCs are placed directly on factory floors, there are many benefits to a motor control center enclosure – a protective structure that houses an MCC. Here’s what you need to know:

What’s an MCC?

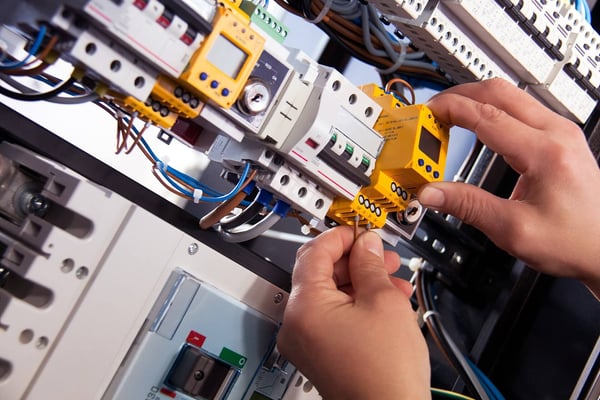

Specifically, a motor control center is an assembly that allows engineers to control electric motors in a central location to help conserve wall or floor space. MCC assemblies may include motor starters, circuit breakers, programmable controllers, metering equipment, and more. The centers will include metal cabinets, various plug-in mounting options, and wireways for field control and power cables to ensure all the machinery is protected and working efficiently.

The Importance of Motor Control Center Enclosures

Placing MCCs next to the machinery it controls is important – that’s why project managers or engineers might consider placing MCCs on the work floor. But in several cases, project leaders prioritize placing the equipment in a motor control center enclosure.

MCCs are often used for companies that work in dusty environments or among corrosive processes. A motor control center enclosure protects vital equipment in a clean, air-conditioned space to keep the machinery running smoothly. If dust or unwanted substances can harm your MCC, a motor control center enclosure is an important element in the success of your equipment operations.

Why Choose a Shipping Container MCC Enclosure?

For project managers and engineers to maintain efficient and well-functioning MCCs, they must develop detailed technical designs, a protective environment for the equipment, and a plan to frequently monitor the equipment.

When MCCs struggle to work properly, the controlled machinery won’t work well, if at all – hindering work processes, delaying project completion dates, and possibly creating a backlog of operational problems.

The managers and engineers most eager to minimize potential MCC mishaps turn to modified shipping containers as motor control center enclosures. Here are a few of the problems related to maintaining MCCs that shipping containers help address:

Protect the MCC Equipment from Temperature, Dust, and Disturbances

Keeping the MCC in top condition requires an enclosure design emphasizing ventilation and air conditioning to protect against machinery overheating, external temperatures, and dust. Manufacturers easily modify shipping containers to include optimal ventilation and air conditioning based on the specifics of a particular MCC, simplifying temperature and dust control. The protective qualities of a shipping container keep the MCC in a well-maintained environment.

Simplify Frequent MCC Monitoring, Maintenance, and Work

Engineers and managers often check on MCCs and perform maintenance on the equipment. Shipping containers improve these tasks with easy equipment installation, custom cable passthroughs, and the ability to place a container unit near controlled machinery – even in limited space.

Simplify equipment installation with shipping containers by loading entirely constructed panels into the enclosure through the cargo doors. Few other equipment enclosures have entire walls that can be opened to install large equipment. Aside from the operable cargo doors, modified containers can have personnel doors to give engineers easy access to the equipment.

Shipping containers can also be customized to meet your specific needs. A common customization is to place cable passthroughs along the walls at specific locations to best accommodate its site location. These customizations and others should be discussed with your container provider.

Additionally, shipping containers are easy to place and relocate. Their compact size allows you to make the most of limited space, so placing a container motor control center enclosure near its controlled machinery is often simple. You don’t have to sacrifice easy accessibility just to house the equipment in an enclosure.

A shipping container-based motor control center enclosure might be the right option for your company. If you’d like to discuss the possibilities of an MCC container, give us a call at 877-704-0177 or email us at Sales@FalconStructures.com. We’re happy to get into the details and set your project in motion.

SUBSCRIBE

- Shipping Container Modifications

- How-Tos

- Workspace

- Commercial Construction

- Multi-Container Buildings

- Storage Solutions

- Industrial Enclosures

- Bathrooms & Locker Rooms

- Oil & Gas

- Climate Control

- Green Building

- Industry Insight

- Living Space

- Military & Training Facilities

- Water Treatment Solutions

- Energy

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

Enhancing the Security of Shipping Container Structures

Marissa Morin | Dec 18, 2019 | 4 min read

READ MORE

Buying Guide: Shipping Container with Roll-Up Door

Marissa Morin | Dec 28, 2022 | 2 min read

READ MORE

Why You Should Turn to Shipping Containers for Your E-House

Marissa Morin | Jun 14, 2023 | 3 min read

READ MORE