How 317 Shipping Containers Became Reliable Remote Terminal Units

Marissa Morin | Mar 18, 2020

Marissa Morin | Mar 18, 2020

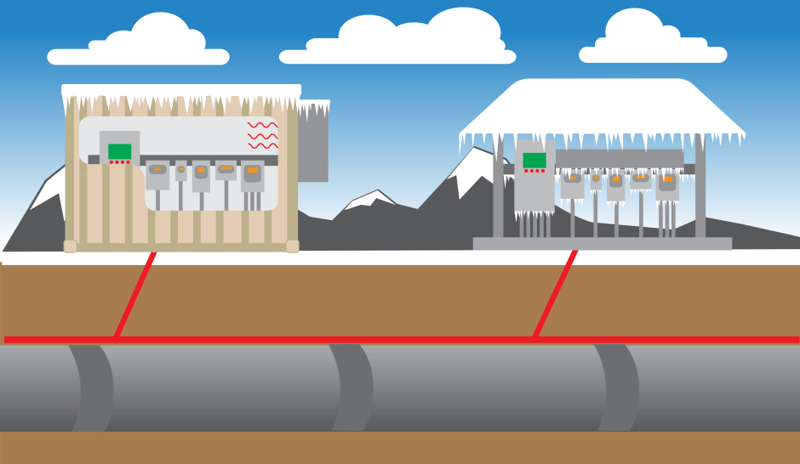

Over a thousand miles of crude oil pipeline runs from the Dakotas to the wetlands of Louisiana. Many unmanned monitoring stations, called remote terminal units (RTUs), sit along the pipeline. Periodically, the RTUs must be serviced and checked – especially in snowy locations – but often go months without attention. Energy Transfer, operator of the Dakota Access Pipeline (DAPL) and the Energy Transfer Crude Oil Pipeline (ETCOP), requested a unique RTU solution. They needed durable remote terminal units that could withstand harsh climates and ship to isolated locations. To meet these needs, we modified 317 10-foot shipping containers into reliable, mobile, and secure RTU structures.

Energy Transfer, like many other mid-stream oil and gas companies, was presented with several remote terminal unit options. One of these options was a bus-style shelter, which often requires a technician to dig the instrumentation out of snow and chisel off layers of ice. Another option was a skid mounted instrument building, which encloses the equipment from the weather, yet takes months to build and comes with a large price tag.

We worked closely with Energy Transfer to develop their ideal remote terminal units: weather tight shipping container structures. Through collaboration, we created accessible and secure units that could handle harsh winters and several feet of snow. Not to mention, each enclosure costs thousands of dollars less than a skid-mounted instrument building.

Why Shipping Containers?

ISO standards for shipping containers already ensure containers can handle wind loads. Built-in forklift pockets also make placing containers on-site — without a skid or foundation — easy. To meet Energy Transfer’s additional requirements, Falcon Structures designed several modifications:

- Weather-tight seals. Energy Transfer wanted a leak-proof solution, even when hosed down with a steady stream of water. Special modifications on the door seals made this a possibility.

- Roofs strong enough for heavy snow loads. Special roof reinforcements support the weight of heavy snowfall and ice.

- Bulkheads for utility pass throughs. We installed a pass through made from thinner metal to make installing and managing machinery easier. Because of this special modification, technicians can easily drill without the need for specialized tools.

In addition to the modifications listed above, the shipping container RTUs included an HVAC system to manage hot and cold climates along the pipeline. Interior lighting helps visiting technicians easily check on equipment.

The Result: Shipping Container Remote Terminal Units

Energy Transfer required quick and reliable completion of the units, so we produced five units every week. For comparison, constructing just one new instrument building using the traditional method often takes months.

For delivery, we sent the units in smaller batches, coordinating with Energy Transfer. Thanks to the modular design of the units, Energy Transfer can quickly replace RTUs with spare containerized units in the future.

As Energy Transfer continues to use these units, they can relocate them as needed. Additionally, the structures will continue to keep the machinery safe from severe weather for many years to come.

If you’d like to hear more about this particular project or if you’d like to request a project of your own, give us a call at 512-231-1010 or email at Sales@FalconStructures.com. We want to create your ideal shipping container project.

SUBSCRIBE

- Shipping Container Modifications

- How-Tos

- Workspace

- Commercial Construction

- Multi-Container Buildings

- Storage Solutions

- Industrial Enclosures

- Bathrooms & Locker Rooms

- Oil & Gas

- Climate Control

- Green Building

- Industry Insight

- Living Space

- Military & Training Facilities

- Water Treatment Solutions

- Energy

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

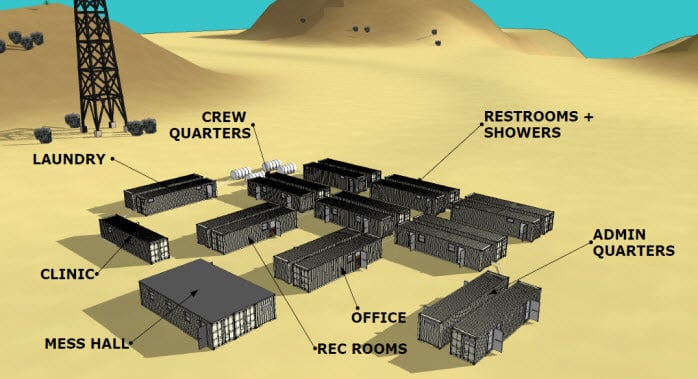

Accommodate Any Size Work Force with Man Camp Housing

Marissa Morin | Sep 16, 2020 | 2 min read

READ MORE

4 Reasons to Use a Shipping Container Prefab Equipment Shelter

Marissa Morin | Mar 22, 2023 | 2 min read

READ MORE

7 Reasons Repurposed Shipping Containers Make Sense

Marissa Morin | Aug 11, 2021 | 3 min read

READ MORE