How the Strength of Shipping Containers Stands Up to Severe Weather

Marissa Morin | Sep 15, 2021

Marissa Morin | Sep 15, 2021

At the turn of the century, steel-framed skyscrapers transformed city skylines. The availability of high-strength and relatively low-cost steel enabled architects to shatter the technical limitations of stone and mortar and build upward. The same can be said for the steel of shipping containers. Thanks to steel and shipping container structural strength, modified containers can be used as building components for everyday structures.

Container manufacturers count on a container’s stability, partly due to the high tensile strength of steel, to manufacture container-based structures. But what is steel and how does it contribute to shipping container structural strength? The answer lies deep in steel’s tiniest building blocks.

Strength of Corten Steel Lattice

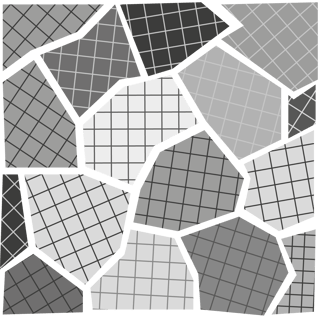

Steel is mostly iron with a small number of other elements, such as carbon and chromium, smelted in. In iron’s pure form, the iron atoms arrange themselves into a cubic lattice as depicted below.

However, pure iron’s atomic arrangement is fairly easy to break and warp, which is why pure iron is relatively soft and malleable to hammering. Introducing differently sized atoms to iron’s lattice creates distortions in the structure. The iron atoms try to hold onto their neat cubic formation but end up bending around the distortions; the perfect cubic mesh begins to run at contrary angles.

In this piece of steel, a larger chromium atom has pushed the iron atoms out of formation, creating distortion to the grain.

Like in lumber and fabrics, the orientation or angle of the atomic pattern is called the grain. While a piece of perfect iron would have one continuous grain, the introduction of imperfections breaks the lattice into many grains that collide with each other. The boundaries between different grains are remarkably ridged and lock up the structure like stiff scars running through softer tissue.

Above is an artistic representation of the atomic structure of steel. The white spaces at the borders of these grains are called grain boundaries. They are significantly more rigid than pure iron’s typical structure.

The strength of steel’s abundant grain boundaries does come with a trade-off: the greater the strength, the less the flexibility. High-carbon – and thus high-strength – steel will snap before it bends. There are construction applications where flexibility is helpful. For instance, it is better for a building to slightly bend during an earthquake than to break. Steel comes in several varieties, called alloys, with different amounts of non-iron elements. Builders must select steel alloys understanding that the strongest choice will also be the most likely to snap.

Shipping containers manufacturers use an alloy, of commonly referred to as “corten steel” or weathering steel. The term “corten” is a combination of the steel’s defining characteristics: “COR-rosion resistance” and “TEN-sile strength.”

To get technical, JIS SPA-H – also known as CORTEN A – is the weathering steel, analogous to the ASTM alloy A242 with a 50ksi yield point and 70ksi tensile strength. In many designs, most components are made with this CORTEN A, but some designs use other alloys in different components. The designs can vary so long as the ISO requirements for loading are met. Manufacturers might choose a different design based on the costs of materials, the weight of the resulting box, and the long-term durability of the unit.

Unpainted, corten steel will form an outer layer of rust that minimizes deeper rust penetration. Many architects and installation artists use corten steel because of the aesthetic appeal of the rusted exterior.

Architects selected corten steel for the Abetxuko Bridge in Vitoria, Spain for longevity and aesthetic reasons. View of the Abetxuko Bridge, by Pontis21, 2006. (CC BY-SA 3.0)

Shipping container experts like Falcon Structures favor corten steel for its protective qualities. We paint shipping containers to prevent rusting, but when the paint does chip, the rust will go no further than the exposed surface. Instead of spreading like a metal-eating rot, the rust forms a protective scab, minimizing damage.

The shipping containers used in this retail structure have a bit of rust at the edges, but still maintain structural integrity. Freita shop entrance, Denna Jones, 2006. (CC-BY-2.0)

Thanks to corten steel, we can count on shipping containers to hold 480,560 lb on their corner castings. The weathering protection is also key to shipping containers’ long-term value retention – 75% for at least 25 years. Corten steel construction is a key reason we’re confident that shipping containers are both a convenient and cost-effective building component for off-site construction. After all, they’re already built from the stuff of skyscrapers.

Shipping Container Safety in Natural Disasters

After understanding shipping container structural strength, a few questions remain: Is a shipping container safe in a tornado? Can a shipping container withstand a hurricane? Of course, the answer depends, just like it does with traditionally constructed buildings. Shipping containers were created to withstand strong winds out at sea, so by taking proper steps to install and secure a modified container, it should be able to withstand a lot of severe weather. Make sure you communicate your severe weather concerns with your container provider, so they can best advise you to consider applicable modifications.

If you’d like more information about modified shipping containers check out our resources page, packed full of case studies, videos, eBooks, and more. If you’d like to get a shipping container project in motion, reach out to our container experts here at Falcon Structures by calling 877-704-0177 or emailing Sales@FalconStructures.com.

SUBSCRIBE

- Shipping Container Modifications

- How-Tos

- Workspace

- Commercial Construction

- Multi-Container Buildings

- Storage Solutions

- Industrial Enclosures

- Bathrooms & Locker Rooms

- Oil & Gas

- Climate Control

- Green Building

- Industry Insight

- Living Space

- Military & Training Facilities

- Water Treatment Solutions

- Energy

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

Enhancing the Security of Shipping Container Structures

Marissa Morin | Dec 18, 2019 | 4 min read

READ MORE

Stacking Shipping Containers Safely: What You Need to Know

Marissa Morin | Jul 26, 2023 | 3 min read

READ MORE

Optimize Your Drill Site with Shipping Container Storage

Marissa Morin | Dec 22, 2021 | 2 min read

READ MORE