What Are Shipping Container Interior Options?

Marissa Morin | Mar 23, 2022

Marissa Morin | Mar 23, 2022

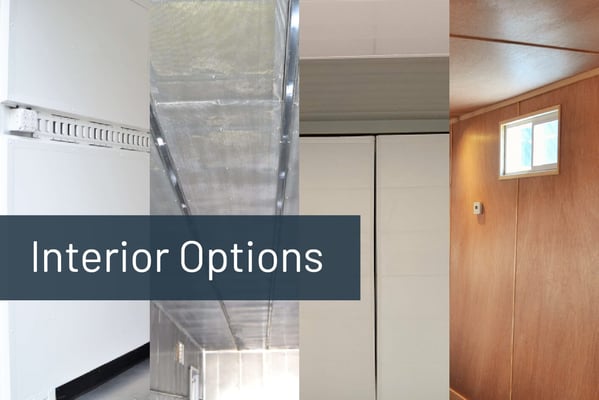

Shipping containers go through a big transformation to make them occupiable. It’s best practice to add insulation and interior finishes to create comfortable, safe, and useful container-based structures. If you’re interested in learning about your options for shipping container interior finishes, we’ve got you covered. From wall paneling to wood and drywall, the following are common shipping container interior options that make the inside of a container feel like any other room.

Shipping Container Drywall

With drywall, a shipping container structure will look exactly like a typical brick and mortar building from the inside. The seams between drywall panels will be invisible once finished and painted. Here at Falcon, our own container-based office building is partly finished out with drywall to create a space that balances the industrial look of the containers with a more traditional office aesthetic.

It’s important to consider how you plan to use your container. If a shipping container is going to become a permanent building, it’s best to install drywall off-site at the manufacturing plant or on-site by a local contractor. On the other hand, if you plan to regularly relocate your container, drywall may not be the best option because over time the vibrations of transportation may crack the walls. Consult with your container structure manufacturer to determine if drywall will work for your project.

Sanded Wood Paneling for a Shipping Container

Sanded wood paneling is a great option for office and living spaces that you plan to relocate down the line. The cabinet-grade wood has a tight grain and smooth finish, keeping the texture from the grain to a minimum. The walls appear smooth once painted over, and trim strips cover the seams between two adjacent panels.

Sanded wood paneling is flexible enough to weather regular relocations without damage, making it ideal for field offices and mobile workforce housing.

Container Plywood Paneling

A plywood interior is less expensive than sanded paneling, but the texture is more pronounced. You can see knots and ripples in the grain even when the plywood is painted over, and the seams between the panels are uncovered. People usually choose plywood paneling for workshops and climate-controlled tool sheds where an interior aesthetic isn’t a priority.

Shipping Container PVC Wall Paneling

PVC wall paneling is lightweight, strong, durable, and water-resistant. Ideal for moisture-laden areas, we utilize this wall option for mobile bathrooms. We usually install PVC wall panels so the interior walls can be hosed down during cleaning.

Steel or Aluminum Sheets for a Container

If you’re looking to create a flame retardant environment for your container structure, steel or aluminum walls might be a good solution. Specifically, we often recommend pairing steel or aluminum interior options with mineral wool or spray foam insulation underneath. We’ve seen metal walls help customers clear customs when moving their container structures overseas protecting highly sensitive equipment.

Perforated Steel for Containers

Industrial equipment is often quite loud, so a growing number of organizations are installing sound deadening insulation covered by perforated steel to create a quiet space for labs and offices. This type of shipping container interior wall paneling is another great option for unique container applications.

Additional Shipping Container Wall Interiors

Other interior options include leaving Styrofoam or spray foam insulation exposed inside a container. We never recommend these choices for living or working environments, only for storage enclosures that need advanced climate control.

What About Permitting?

While policies range from county to county, mobile container structures are generally treated like trailers or RVs, and thus installing walls and electrical off-site is often completely fine. However, if the container will be part of a permanent structure, your local authority having jurisdiction will likely want an inspector to check the wiring, framing, and plumbing before you add paneling. This is why it’s vital you loop in local professionals if you have permitting concerns.

If you’d like more information about shipping containers check out our resources, if you’d like to discuss a specific project, give us a call at 512-231-1010 or contact us online. We’re happy to answer your questions.

SUBSCRIBE

- Shipping Container Modifications

- How-Tos

- Workspace

- Commercial Construction

- Multi-Container Buildings

- Storage Solutions

- Industrial Enclosures

- Bathrooms & Locker Rooms

- Oil & Gas

- Climate Control

- Green Building

- Industry Insight

- Living Space

- Military & Training Facilities

- Water Treatment Solutions

- Energy

THINK INSIDE THE BOX®

WITH OUR BLOG

Get everything from shipping container basics, to detailed how-tos and industry news in our weekly blog. Stay inspired and subscribe!

RELATED BLOGS

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=360&name=Converted%20office%20container%20feature%20blog%20image.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=480&name=Converted%20office%20container%20feature%20blog%20image.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=720&name=Converted%20office%20container%20feature%20blog%20image.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=768&name=Converted%20office%20container%20feature%20blog%20image.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1350&name=Converted%20office%20container%20feature%20blog%20image.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1440&name=Converted%20office%20container%20feature%20blog%20image.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1920&name=Converted%20office%20container%20feature%20blog%20image.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=2278&name=Converted%20office%20container%20feature%20blog%20image.jpg 2278w"

loading="lazy">

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=360&name=Converted%20office%20container%20feature%20blog%20image.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=480&name=Converted%20office%20container%20feature%20blog%20image.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=720&name=Converted%20office%20container%20feature%20blog%20image.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=768&name=Converted%20office%20container%20feature%20blog%20image.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1350&name=Converted%20office%20container%20feature%20blog%20image.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1440&name=Converted%20office%20container%20feature%20blog%20image.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=1920&name=Converted%20office%20container%20feature%20blog%20image.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Converted%20office%20container%20feature%20blog%20image.jpg?width=2278&name=Converted%20office%20container%20feature%20blog%20image.jpg 2278w"

loading="lazy">

Shipping Container Converted to an Office? What's Possible with Falcon

Becca Hubert | Feb 21, 2024 | 4 min read

READ MORE

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=360&name=20ft_office.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=480&name=20ft_office.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=720&name=20ft_office.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=768&name=20ft_office.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1350&name=20ft_office.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1440&name=20ft_office.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1920&name=20ft_office.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=2278&name=20ft_office.jpg 2278w"

loading="lazy">

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=360&name=20ft_office.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=480&name=20ft_office.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=720&name=20ft_office.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=768&name=20ft_office.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1350&name=20ft_office.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1440&name=20ft_office.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=1920&name=20ft_office.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/b.%20blog%20page/20ft_office.jpg?width=2278&name=20ft_office.jpg 2278w"

loading="lazy">

Same Floor Plan, Different Solution: The Many Uses of a 20ft Container

Marissa Morin | Oct 26, 2022 | 3 min read

READ MORE

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=360&name=Top%20container%20uses%20feature%20image.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=480&name=Top%20container%20uses%20feature%20image.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=720&name=Top%20container%20uses%20feature%20image.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=768&name=Top%20container%20uses%20feature%20image.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1350&name=Top%20container%20uses%20feature%20image.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1440&name=Top%20container%20uses%20feature%20image.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1920&name=Top%20container%20uses%20feature%20image.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=2278&name=Top%20container%20uses%20feature%20image.jpg 2278w"

loading="lazy">

What Are Shipping Container Interior Options? featured image" srcset="https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=360&name=Top%20container%20uses%20feature%20image.jpg 360w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=480&name=Top%20container%20uses%20feature%20image.jpg 480w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=720&name=Top%20container%20uses%20feature%20image.jpg 720w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=768&name=Top%20container%20uses%20feature%20image.jpg 768w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1350&name=Top%20container%20uses%20feature%20image.jpg 1350w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1440&name=Top%20container%20uses%20feature%20image.jpg 1440w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=1920&name=Top%20container%20uses%20feature%20image.jpg 1920w,https://www.falconstructures.com/hs-fs/hubfs/5.%20images/a.%20blog%20featured/Top%20container%20uses%20feature%20image.jpg?width=2278&name=Top%20container%20uses%20feature%20image.jpg 2278w"

loading="lazy">

Top 6 Shipping Container Uses

Becca Hubert | Mar 20, 2024 | 3 min read

READ MORE